As an established EMS service provider, we produce high-quality printed circuit boards in batches of 1 to 10,000 pieces, according to your specifications. We manufacture on ultra-modern machines, and address complex requirements for you. We understand how to produce efficiently and fairly at our site in Austria. We keep communication and delivery channels short, save you long waits and avoid language barriers. And we choose the best-suited assembly technique: SMT assembly for single- and double-sided PCB assembly, THT assembly for larger components or a mixed form.

SMD assembly. Our fast lane for your electronic assembly.

Our modern SMT placement machines are designed to ensure high quality and short throughput times. Our machines assemble boards with up to 1,200 components per minute. All common component shapes from 01005 to THR components are processed here. Economic efficiency is a top priority for us. Every step of the process must fit perfectly, especially in the case of very small series. Our flexible production lines create short set-up and reaction times. Through optimized logistics and professional storage, we ensure your printed circuit boards are assembled to a high standard and produced quickly and at economically attractive conditions, even in small series.

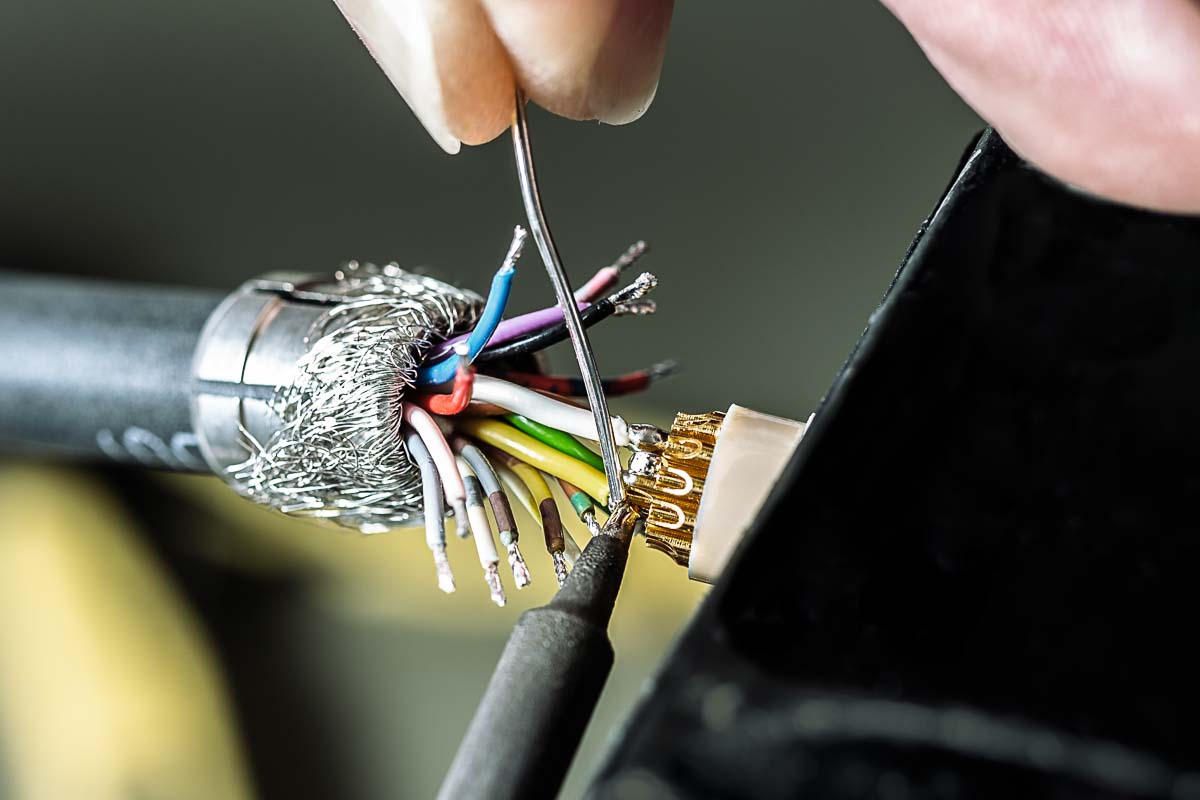

Soldering and coating. It's the finishing that counts.

Depending on the selected assembly technology, we use different soldering techniques: vapor phase soldering; reflow soldering; selective soldering; wave soldering. For special components that can't be processed with any machine, our trained personnel still reach for the soldering iron.

In order to protect the printed circuit board from environmental influences in the final application, we choose coating techniques such as dip coating (fluoropolymer), selective coating, potting or bonding.

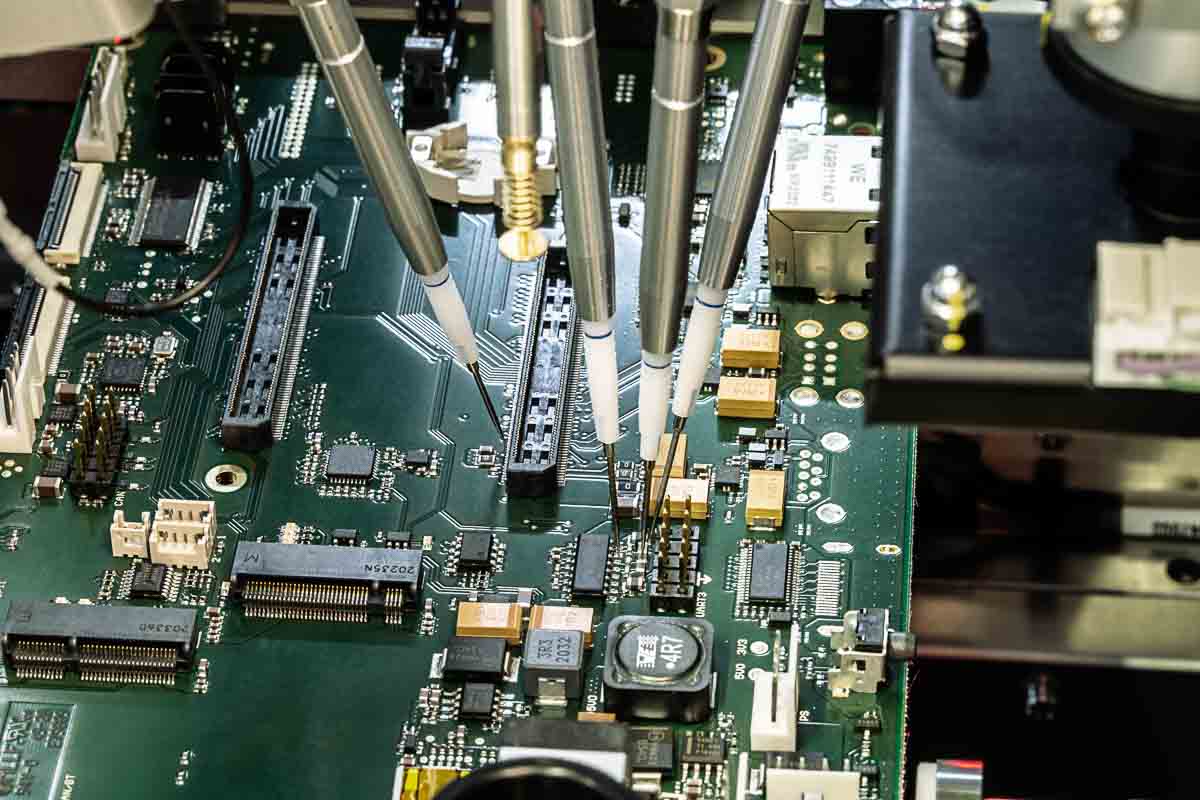

Superb quality. Through effective audit controls.

Defective printed circuit boards always lead to unpleasant product failures. Our clients include companies from various industries such as medical technology and aviation. They demand top quality and 100% reliability. So in addition to standard optical test routines such as AOI and Quins, we also use in-circuit tests and flying probe test systems to test component and solder quality. With our flying probe tester we achieve a test coverage in the functional test of up to 98 %. In addition, we manufacture customer-specific functional test adapters tailored to your boards.

For you this means: early error identification; bug fixing already for prototypes; maximum functional reliability of your electronic components in series production; no downtime costs.

Any questions? Contact us!